A tool for the future of medical technology

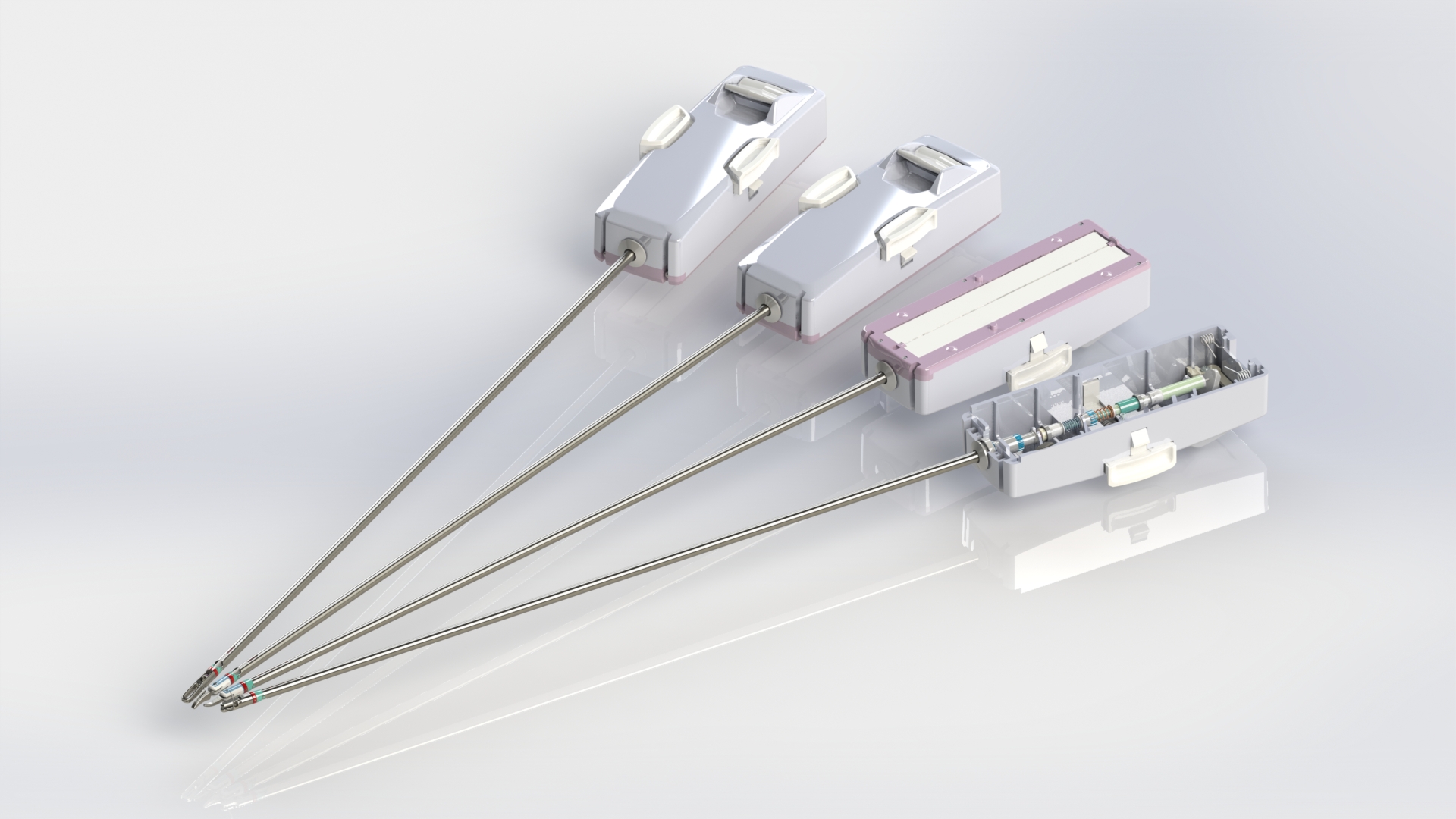

In modern surgery, precision is not an option, but a prerequisite. Every detail counts, especially in minimally invasive, robot-assisted procedures—from the robot’s first control pulse to the movement at the active tip. Our task: the complete mechanical development of a medical device that not only meets this precision requirement, but also sets new standards.

The project began with a clear goal – maximum reliability, highest precision, and uncompromising sterility – implemented in a compact, robust, and user-friendly system. What initially appeared to be a classic design project quickly became an interdisciplinary challenge: motion mechanics in a very confined space, repeatable interfaces to robotics, materials with maximum long-term stability – and all this under the requirements of a strict regulatory framework.

The core of the system is the highly precise motion transmission, which has been optimized via a complete 3D tolerance analysis from the robot interface to the active tip. No play, no deviation—every micrometer counts. Through targeted compensation tolerances and intelligent coupling concepts, we have ensured that the instrument functions reliably even after repeated attachment and removal – without readjustment.

We are particularly proud of the connection technology we have developed between stainless steel and ceramic. Through targeted adhesive testing with different epoxy and silicone adhesives, as well as mechanical adjustments, we have been able to create a hybrid structure that is suitable for sterilization and remains tight, secure, and functional even after more than 100 autoclave cycles.

Usability? For us, this is not an afterthought, but an integral part of the development process. All interfaces are intuitive to the touch and visually intuitive, and can even be operated with surgical gloves. The instrument can be assembled and cleaned without tools – in seconds. And hospital staff confirm that this is finally a system that can be used under real conditions – even under time pressure.

At the same time, we have focused on a design suitable for series production: fewer components, injection-molded design, reduced assembly times—all while maintaining consistent performance. A well-thought-out concept that impresses not only in the operating room, but also in production and service.

The end result is an instrument that makes a difference: technologically precise, easy to understand, and designed for practical use. For us, it is more than just a project—it is a contribution to the future of surgery.

B&W hat unsere Vision für ein surgical Instrument nicht nur verstanden, sondern messbar besser gemacht. Denn Instrumente entwickeln viele – B&W macht sie spürbar besser.